Well defined analyzed spot: The figures show the area of the sample measured by the analyzer. The right picture shows the sample imaged in SEM mode using the secondary electron signal. The left picture is the same image collecting the signal through the spectrometer. The acceptance area is easily measured by scanning the electron beam of the integral electron gun over the sample. Only a well defined circular area of about 2 to 3 mm diameter is accepted. Small spot XPS and UPS analyses are thus possible and, in contrast to many spectrometers,the surrounding area of the sample or of the sample holder are not contributing to the detected signal.

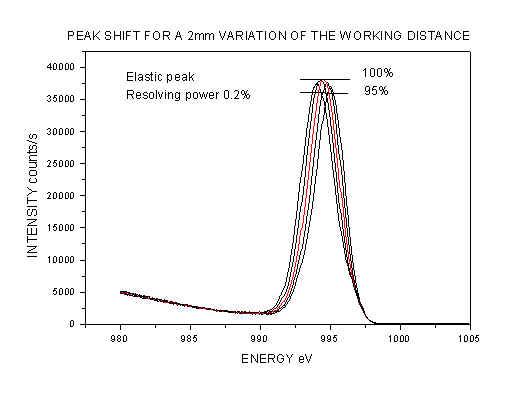

Another major advantage of the SUPERCMA is that the positioning of the sample in front of the analyzer is not critical. The diagram shows the shape variations of the elastic peak measured at a resolving power of 0.2%. A variation of 2 mm around the optimum position ensures a transmission at 96% of the maximum. In fact, variations of the working distance up to + 3mm are acceptable for performing routine AES and ELS.

Unequaled energy stability: The energy position of the peaks vs. sample position is not critical .The energy shift is less than 0.05% of the primary energy for a variation of 1 mm of the working distance. This means that the energy calibration remains valid even after shifting, rotating, tilting, or changing the sample.

Application to gaseous samples: The SUPERCMA has a well defined acceptance volume, which is the volume of a cylinder defined by the accepted area times the axial length of the source, i.e., 6 to 8 mm3. This large volume, together with the large angular acceptance angle of the spectrometer, provides unsurpassed sensitivity for analyzing gaseous samples. |